Conserve Resources and Reduce Costs

In the pooling system, re-usable transport packaging like pallets or plastic containers are used collectively. Companies that need these packages can borrow them from our central pool.

After use, the returnable transport packaging is given back, optionally cleaned by us, and then flows back into the pool. This cycle allows for better utilization of existing resources, reduction of waste, and minimization of costs for storing and transporting empty packaging. Through our extensively developed network across Europe, we keep every transport route short, combine transports of different customers, and thus actively reduce CO2 emissions.

Furthermore, pooling also offers the opportunity to reduce stock levels and release capital, as companies no longer need to invest in large quantities of packaging. Instead, they can flexibly respond to their current projects and focus on their day-to-day business.

Would you like to find out more about pooling?

Closed Pooling Loop

-

1. Grower

The returnable packages with the food, raw products, or ingredients are transported to businesses that process the delivered goods. Since our reusable solutions are suitable as primary, secondary, and tertiary packaging, they can continue to be used even after further processing.

-

2. Industry

When it comes to food that is not directly suitable for further processing, our reusable packaging can also cover the intermediate step from animal breeding to the slaughterhouse and from there on to the final processor.

The advantages are obvious: food-safe material, robust properties for particularly sensitive and raw goods and perfect hygiene conditions. -

3. Processing

The reusable packaging with the food, raw products or ingredients is transported to companies that further process the delivered goods.

As our reusable solutions are suitable as primary, secondary and tertiary packaging, they can also be used continuously after further processing. -

4. Retail Distribution Center

Once they arrive at the retailer’s central warehouse, the goods are pre-picked and temporarily stored for further transportation. The advantage of our reusable containers and pallets is that they have both industrial and Euro dimensions and are also suitable for automated storage locations!

-

5. Retail Store

Ihre Ware hat es bis fast bis zum Endkonsumenten geschafft! Auch in Geschäften des Lebensmitteleinzelhandels können unsere Mehrwegverpackungen weiteren Einsatz finden und ansprechend in der Auslage präsentiert werden; so lässt sich auch hier viel Einwegmüll einsparen!

-

6. Retail Distribution Center

The used load carriers are then taken from the central warehouse to one of our service locations, where the packaging is sorted, repaired if necessary and, above all, cleaned and disinfected so that it is ready for its next use.

-

7. Service Center

The cleaned crates, pallets and containers are returned from the service center to producers and manufacturing companies in order to transport high-quality food again and thus reduce food waste quotas within the supply chain.

-

back to the start

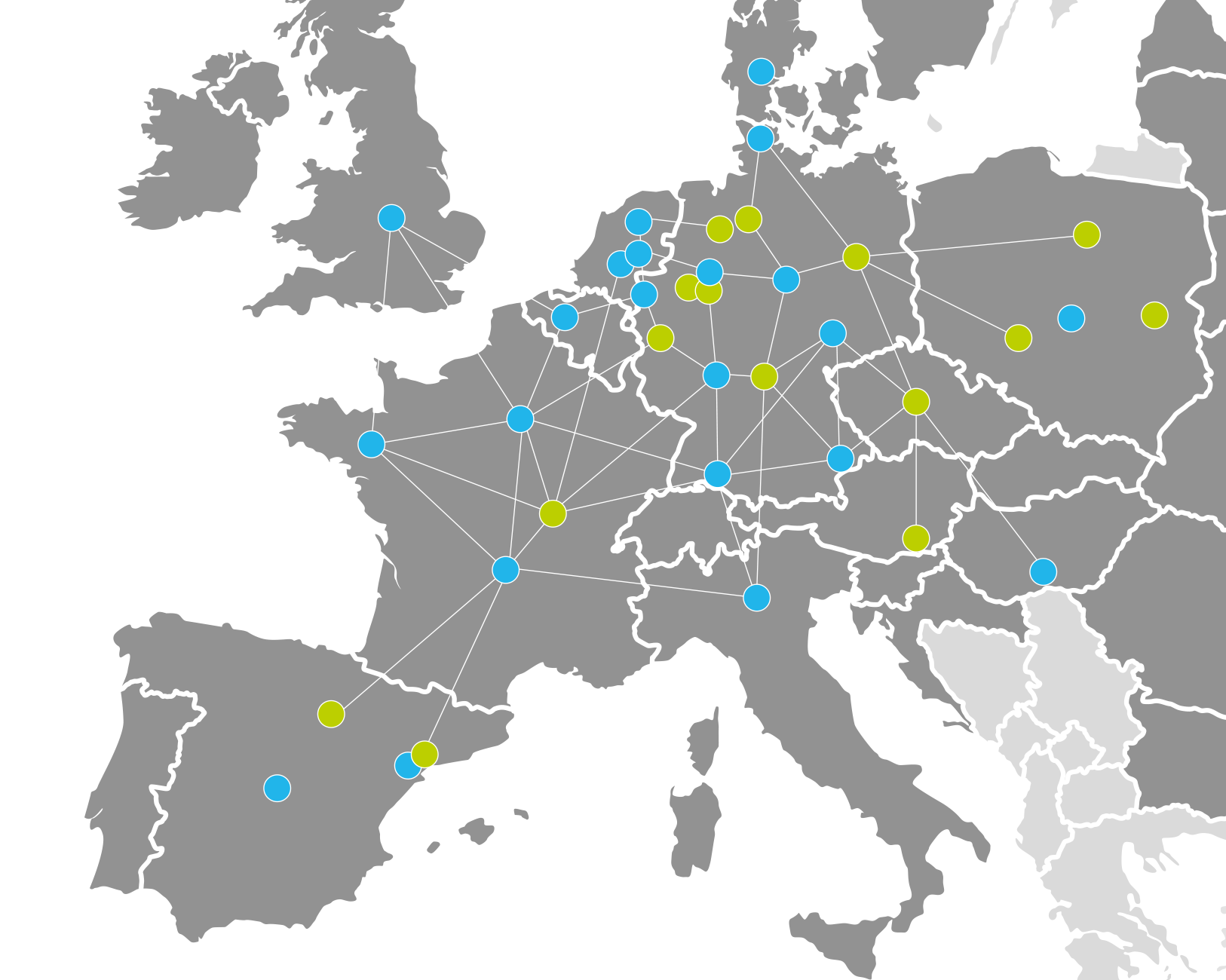

The WBG Pooling Network in Europe

From logistical, operational and administrative processing to the cleaning, disinfection and repair of reusable transport packaging, we are committed to the circular economy and avoid waste and actively reduce greenhouse gases through our European pooling network. As a logistics service provider, WBG Pooling covers the entire food supply chain and can guarantee full service from a single source.

We offer:

- High-quality reusable transport packaging for every product group

- A Europe-wide network of warehouse and service locations

- Logistical coverage at peak times

- Digitalised processes from the field to retail

Would you like to find out more about our network and our service locations?